Masters

SANAA – Sejima and Nishizawa and Associates: The Detail and the Legislation

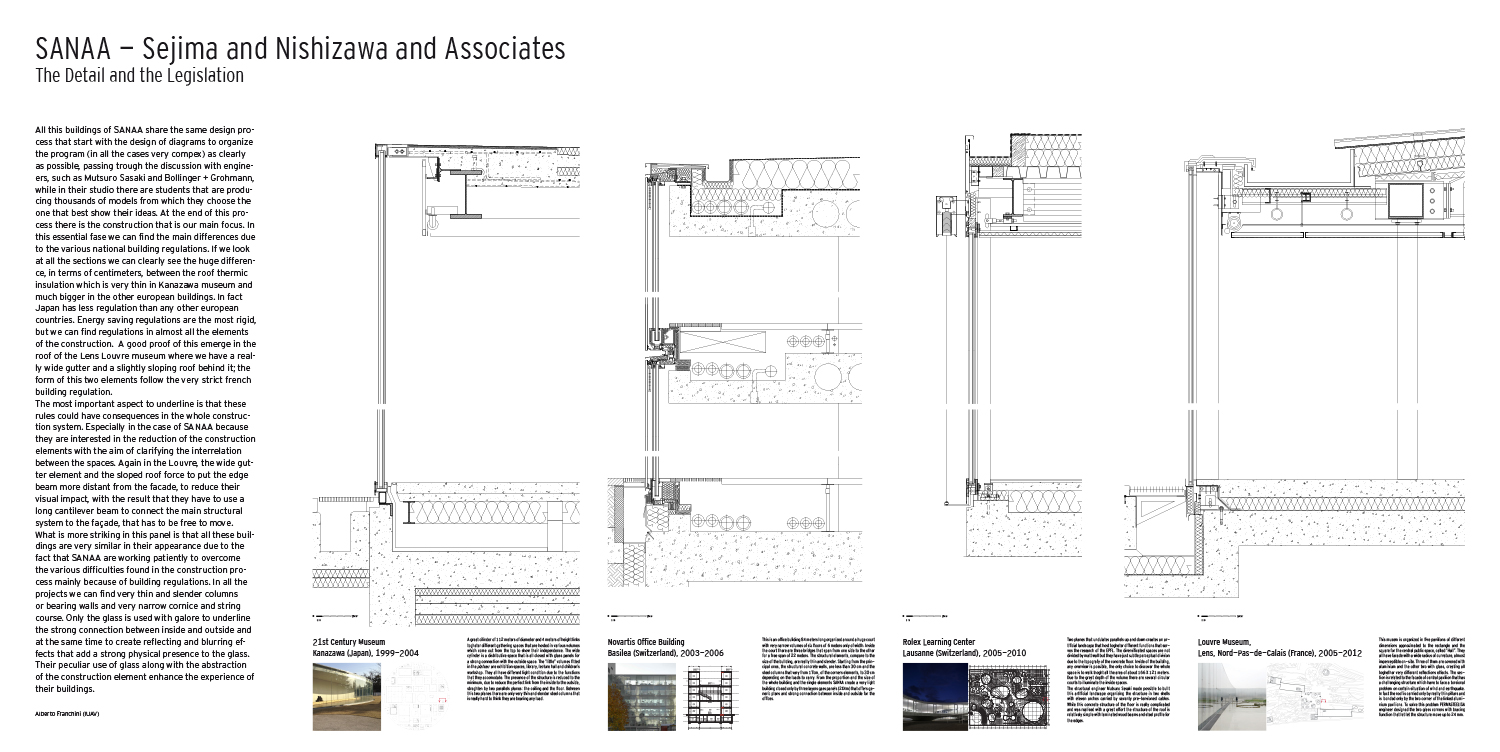

All this buildings of SANAA share the same design process that start with the design of diagrams to organize the program (in all the cases very compex) as clearly as possible, passing trough the discussion with engineers, such as Mutsuro Sasaki and Bollinger + Grohmann, while in their studio there are students that are producing thousands of models from which they choose the one that best show their ideas. At the end of this process there is the construction that is our main focus. In this essential fase we can find the main differences due to the various national building regulations. If we look at all the sections we can clearly see the huge difference, in terms of centimeters, between the roof thermic insulation which is very thin in Kanazawa museum and much bigger in the other european buildings. In fact Japan has less regulation than any other european countries. Energy saving regulations are the most rigid, but we can find regulations in almost all the elements of the construction. A good proof of this emerge in the roof of the Lens Louvre museum where we have a really wide gutter and a slightly sloping roof behind it; the form of this two elements follow the very strict french building regulation.

The most important aspect to underline is that these rules could have consequences in the whole construction system. Especially in the case of SANAA because they are interested in the reduction of the construction elements with the aim of clarifying the interrelation between the spaces. Again in the Louvre, the wide gutter element and the sloped roof force to put the edge beam more distant from the facade, to reduce their visual impact, with the result that they have to use a long cantilever beam to connect the main structural

system to the façade, that has to be free to move.

What is more striking in this panel is that all these buil-dings are very similar in their appearance due to the fact that SANAA are working patiently to overcome the various difficulties found in the construction process mainly because of building regulations. In all the projects we can find very thin and slender columns or bearing walls and very narrow cornice and string course. Only the glass is used with galore to underline the strong connection between inside and outside and at the same time to create reflecting and blurring effects that add a strong physical presence to the glass. Their peculiar use of glass along with the abstraction of the construction element enhance the experience of their buildings.

Alberto Franchini (IUAV)

Read text

21st Century Museum

Kanazawa (Japan), 1999-2004

A great cilinder of 112 meters of diameter and 4 meters of height links togheter different gathering spaces that are hosted in various volumes which come out from the top to show their independence. The wide cylinder is a distributive space that is all closed with glass panels for a strong connection with the outside space. The “little” volumes fitted in the plateau are exhibition spaces, library, lecture hall and children’s workshop. They all have different light condition due to the functions that they accomodate. The presence of the structure is reduced to the minimum, due to reduce the perfect link from the inside to the outside, streghten by two parallels planes: the ceiling and the floor. Between this two planes there are only very thin and slender steel columns that is really hard to think they are bearing any load.

Novartis Office Building

Basel (Switzerland), 2003-2006

This is an office building 84 meters long organized around a huge court with very narrow volumes of six floors of 6 meters only of width. Inside the court there are three bridges that span from one side to the other for a free span of 22 meters. The structural elements, compare to the size of the building, are really thin and slender. Starting from the principal ones, the structural concrete walls, are less than 30 cm and the steel columns that vary from 17cm, of the corners elements, to 30 cm depending on the loads to carry. From the proportion and the size of the whole building and the single elements SANAA create a very light building closed only by three layers gass panels (2X4m) that offers generic plans and strong connection between inside and outside for the offices.

Rolex Learning Center

Lausanne (Switzerland), 2005-2010

Two planes that undulates parallels up and down creates an artificial landscape that host togheter different functions that serves the research of the EPFL. The diversificated spaces are not divided by matt wall but they have just subtle perceptual division due to the topografy of the concrete floor. Inside of the building, any overview is possible, the only choice to discover the whole space is to walk troght all the area of about 166 X 121 meters. Due to the great depth of the volume there are several circular courts to illuminate the inside spaces.

The structural engineer Mutsuro Sasaki made possible to built this artificial landscape organizing the structure in two shells with eleven arches carried by seventy pre-tensioned cables. While this concrete structure of the floor is really complicated and was realised with a great effort the structure of the roof is relatively simple with laminated wood beams and steel profile for the edges.

Louvre Museum,

Lens, Nord-Pas-de-Calais (France), 2005-2012

This musem is organized in five pavilions of different dimensions approximated to the rectangle and the square for the central public space, called “Hall”. They all have facade with a wide radius of curvature, almost imperceptible on-site. Three of them are covered with aluminium and the other two with glass, creating all toghether very different reflections effects. The section is related to the facade of central pavilion that has a challenging structure which have to face a torsional problem on certain situation of wind and earthquake. In fact the roof is carried only by really thin pillars and is bonded only by the two corner of the linked aluminium pavilions. To solve this problem PERMASTEELISA engineer designed the two glass corners with bracing function that let let the structure move up to 24 mm.